By Ellie Gabel

Are collaborative robots the key to transforming robotics education and closing technical skills gaps? Cobots have numerous advantages over traditional industrial robots, including greater flexibility and easier programming. These traits are perfect for enhancing robotics training with hands-on collaboration that teaches technical creativity and vital workplace skills.

Collaborative Robots in Education

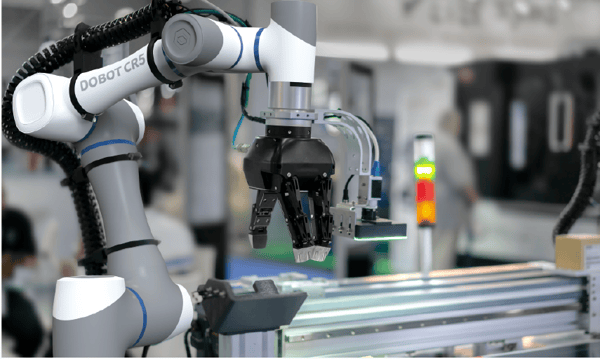

Collaborative robots, or “cobots,” are gaining popularity in the workplace and education. At first glance, they might look like any other robotic arm or tool. However, they have a unique advantage that other robots don’t: cobots are designed to work safely alongside people.

Studies show robots are directly responsible for at least 30 workplace accidents annually. Mental health side effects caused by competition between robots and humans can lead indirectly to more workplace stress, anxiety, errors and physical injuries. Traditional industrial robots can also be complex to operate, further increasing employee stress.

In contrast, collaborative robots are designed from a human-first viewpoint. Safety and accessibility are the top priorities. Cobots tend to be more user-friendly and much less dangerous to work with. As a result, they’re ideal for training the next generation of robotics technicians and engineers.

Closing the Manufacturing Skills Gap

Robots and automation are emerging as the future of the manufacturing industry, but they’re creating a new issue: a skills gap. Today’s workforce lacks the advanced skills and knowledge needed to successfully operate and maintain robots. This labor shortage will grow to 2.1 million roles by 2030.

The top solution to this problem is improving tech literacy among current and future manufacturing employees. Safe, in-depth educational programs are the key to accomplishing this. Collaborative robots are a great tool for teaching robotics skills since they are typically significantly safer to operate than conventional bots.

Labor shortages are one of the main factors driving market growth for cobots today. These robots are suitable for high school robotics and career training, as well as technical colleges and trade schools. Students can get a hands-on learning experience without fear of being injured during training.

Hands-on, high-tech training can make a big difference in bridging the skills gap. Collaborating with robots could attract more young people to technical careers like manufacturing. Gen-Z students are widely excited about technology and tech-focused jobs. Instructors can use cobots to show them how cutting-edge modern manufacturing careers are.

Why Collaborative Robots Are the Future

There are many ways collaborative robots can transform education and the workplace. Their sheer flexibility makes these machines stand out among today’s many innovations in the industry. Cobots are highly adaptable to classroom settings and serve many purposes in the workplace, from helping employees to automating unfilled roles.

For example, a manufacturer can buy a few units of the same cobot model and apply them in various ways. One might screw in bolts while another passes items down an assembly line. The robots can be reprogrammed with a user-friendly interface if workplace needs change.

This adaptability is highly advantageous in education. It allows students to build creativity, particularly in the context of engineering. Technical creativity requires problem-solving and a clear understanding of a robot’s capabilities. Cobots can help students develop this unique skill set through open-ended, flexible programming.

In contrast, traditional robots are typically designed to perform one specific task. This can work fine in a static environment but isn’t conducive to flexibility or learning. Cobots allow students to learn a wider range of programming tools and skills to work with more types of robots. As a result, the next generation of the robotics workforce will be better equipped to find innovative solutions and applications for automation technologies.

What Industries Are Using Cobots?

What industries can students work in after learning to program and work with cobots? Cobot adoption has grown steadily over recent years. The collaborative robot market was valued at about $700 million in 2021. By 2030, it could hit $1.9 trillion worldwide.

End effectors are the name of the game when it comes to cobot applications. Many cobots can perform dozens of tasks by simply swapping out the end of arm tooling. As a result, a basic six-axis cobot arm can become highly popular in many applications.

Manufacturing is leading the growth in the collaborative robotics market. A need for greater efficiency, combined with a widespread labor shortage, makes this sector a perfect match for cobots. They are often used for tasks like machine tending, quality control and process automation. There’s much variety in the types of processes cobots automate, ranging from sorting to welding.

Logistics is also seeing an increase in collaborative robots. Cobots are great for tasks like palletizing and pick-and-place applications. They can pack and sort boxes without posing a risk to employees in fast-paced environments.

Cobots: The Key to Collaborative Robotics Education

Collaborative robots are transforming STEM education, helping close critical skills gaps across multiple industries. Cobots are flexible, adaptable and easy to program. These qualities make them much more accessible for employees and versatile for businesses. Adopting cobots can strengthen robotics education programs, equipping the workforce of tomorrow with invaluable technical skills.

Want to learn more about Cobots?

Check more here: