There are a few key differences between a traditional factory and an Industry 4.0 factory. In the current industry environment, providing a high-end quality service or product with the least cost is the key to success. Industrial factories want to achieve as much performance as possible to increase their profit as well as their reputation.

In a traditional factory, various data sources are available to provide worthwhile information about different aspects of the factory. With this type of format, the utilization of data for understanding current operating conditions and detecting faults and failures is an important topic to research.

For example, in production, there are various commercial tools available to provide overall equipment effectiveness (OEE) information to factory management. These tools are used to highlight the root causes of problems and possible faults in the system. However,, in an Industry 4.0 factory, in addition to condition monitoring and fault diagnosis, components and systems can gain self-awareness and self-predictiveness, which will provide management with more insight on the status of the factory.

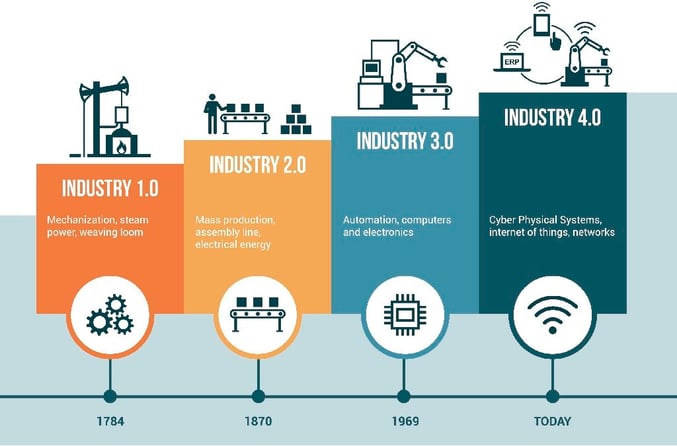

The Industry 4.0 roadmap visualizes every next step on the route towards an entirely digital enterprise.

To achieve success in the digital transformation process, it is necessary to prepare the technology roadmap in the most accurate way. In today’s business, Industry 4.0 is driven by the digital transformation of vertical/horizontal value chains and product/service offerings of the companies. The required key technologies for the Industry 4.0 transformation , such as artificial intelligence, internet of things, machine learning, cloud systems, cybersecurity, and adaptive robotics, cause radical changes in the business processes of organizations.

How can you implement this technology in the classroom?

A great tool to prepare your students for this change is Dobot Magician, a truly cutting-edge robotic arm that is available for your STEAM or CTE program. It's a highly cost-effective solution empowering 21st century skills and unleashing students' creativity. Dobot integrates programming, mechanics, electronics, and automation. It’s a great STEAM teaching device that strengthens student knowledge across multiple subjects through a high precision and user-friendly UI, enjoyable functions, and unlimited developing possibilities. Dobot Magician brings Industry 4.0 and the new era to life for your students.

Stay tuned for more blog posts about the Industry 4.0 and learn about this amazing new digital era.

Are you Interested in having Dobot in your classroom? Ask for a price quote request.