My LittleBits Don't Stick to Structure Surfaces

Potential Solutions to Try:

- Jul 18, 2018 5:36:21 PM

- Posted by Anna Sandler

- Topics: Troubleshooting & Warranties, LittleBits

My LittleBits LED Won't Light Up

Potential Solutions to Try:

- Jul 18, 2018 5:30:46 PM

- Posted by Anna Sandler

- Topics: Troubleshooting & Warranties, LittleBits

My LittleBits Connectors Have Adhesive Residue On Them

Potential Solutions to Try:

- Jul 18, 2018 5:28:12 PM

- Posted by Anna Sandler

- Topics: Troubleshooting & Warranties, LittleBits

My LittleBits Motors Are Not Working Properly

If your Little-Bits motors are running slowly, or one of the motors lags behind, here are some things you should try:

- Jul 18, 2018 5:24:46 PM

- Posted by Anna Sandler

- Topics: Troubleshooting & Warranties, LittleBits

My LittleBits Circuit Isn't Working

Potential Solutions to Try:

- Jul 18, 2018 5:19:50 PM

- Posted by Anna Sandler

- Topics: Troubleshooting & Warranties, LittleBits

How To Take Care of LittleBits in the Classroom

Keeping Your Bits Organized

- Jul 18, 2018 5:07:25 PM

- Posted by Anna Sandler

- Topics: Troubleshooting & Warranties, LittleBits

How To Fix Malfunctioning LittleBits

Please try the following before you contact our support if one of your LittleBits doesn't work:

- Jul 18, 2018 4:52:59 PM

- Posted by Anna Sandler

- Topics: Troubleshooting & Warranties, LittleBits

3D Printer Filament Is Stuck

Filament can swell inside the extruder and get stuck.

If you cannot unload filament from one of the extruders, do the following:

1. On the LCD panel, navigate to Utilities > Change Filament > Unload. This option heats the extruders.

- Jul 18, 2018 4:13:58 PM

- Posted by Anna Sandler

- Topics: MakerBot, 3D-Printer

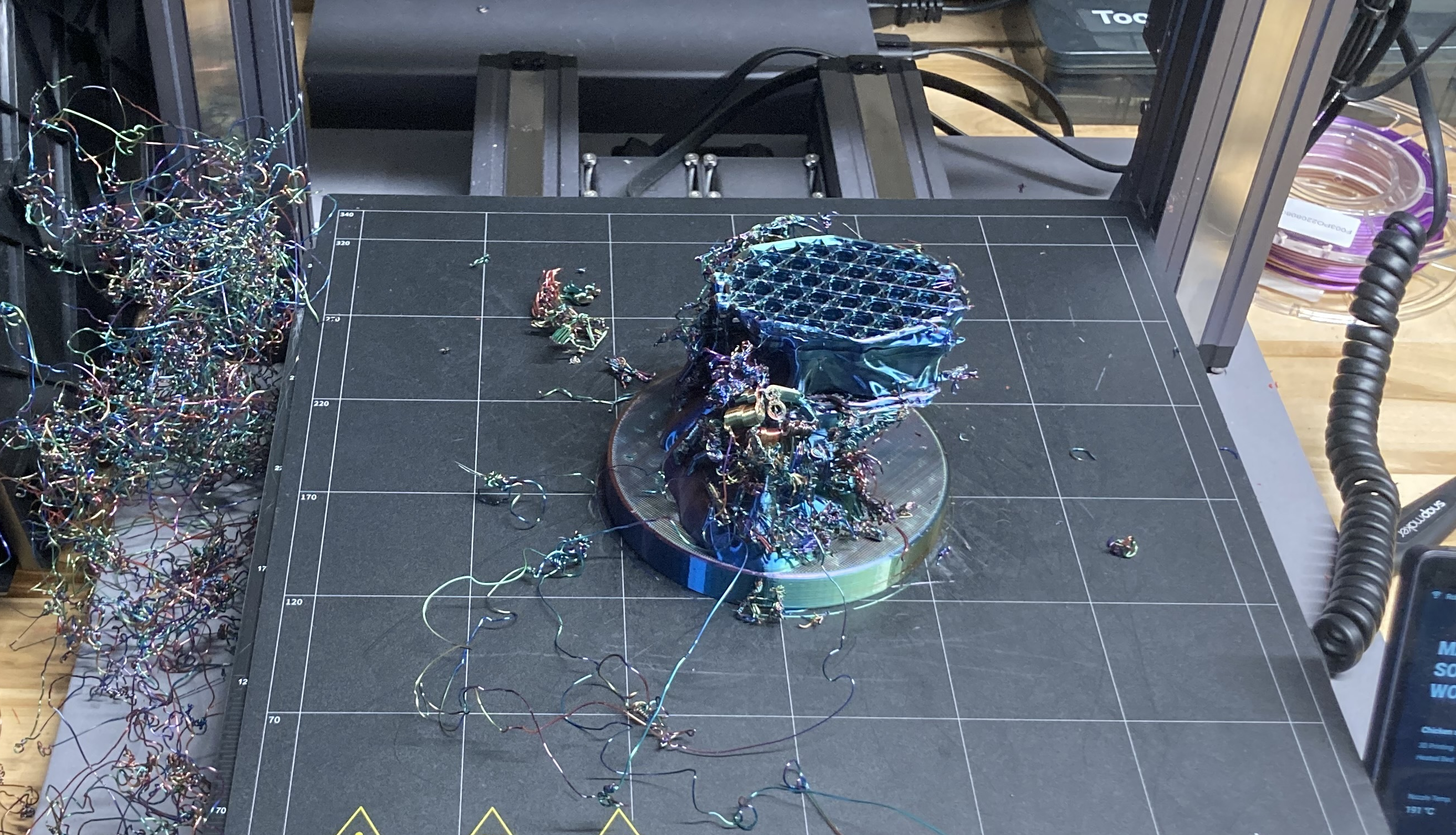

How to 3D Print With The Most Quality Guide

Cracks, Warping, Rippling, Drift... Tips to help your projects look their best on the very first try.

- Jul 18, 2018 2:42:50 PM

- Posted by Anna Sandler

- Topics: Troubleshooting & Warranties, MakerBot, 3D-Printer

3D Printer Safety Instructions

Dos and don'ts

- Jul 18, 2018 2:25:10 PM

- Posted by Anna Sandler

- Topics: Troubleshooting & Warranties, MakerBot, 3D-Printer

Email Support

Email Support

If you’re unable to find an answer on our website, fill out the form below to start a ticket. We normally aim to respond to all emails within a few days.

Call-in support

Call-in support

Our support engineers are standing by to help.

+1 (415) 702-3033-

I Want To Learn MoreADDITIONAL INFORMATION

Email Support

Email Support Call-in support

Call-in support