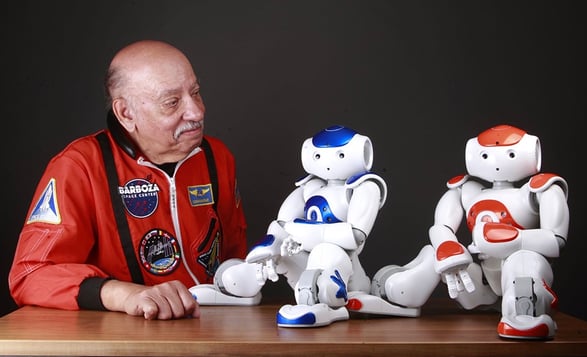

Feature a Teacher: Using NAO as a tool for learning and as an adventure program simulator.

Bob Barboza is an educator, STEM journalists, composer and founder of the Barboza Space Center STEM & STEAM fellowship Program and Kids Talk Radio Science. http://www.barbozaspacecenter.com/ He trains Jr. astronauts, engineers, and scientists for the "Occupy Mars Learning Adventures." His students and interns are learning robot and satellite design, building, and repair.

- 0 Comments

- Apr 25, 2018 4:03:04 PM

- Posted by Maria Alejandra Calcetero

- Topics: Education, NAO, Robots,

Feature a Teacher: NAO as an interactive tool to develop new Artificial Intelligence methodologies

Sam Thangiah is a Professor/ Director, Artificial Intelligence and Robotics Lab at Slippery Rock University – Computer Science Department and he has been using the NAO Robot to read stories for K-1 students, interact with autistic children and develop implementation of AI methods in the robo. Due to the sensors and the capability of the robot to program with the API provided, Mr. Thangiah realized that NAO robot is the best tool for him.

- 0 Comments

- Apr 25, 2018 4:01:04 PM

- Posted by Maria Alejandra Calcetero

- Topics:

Feature a Teacher: NAO as an emotional robot for students

Mauro Colucci a Mechatronics teacher, and Maila Biaggi a English language teacher at Vocational School’G. Marcelli’- http://www.scuolafoiano.gov.it/ they have been using the NAO Robot for two years when the school was looking for an emotional robot completely programmable that could have a strong impact on the students. they met NAO Robot and since then, they realized it was the perfect tool for them.

- 0 Comments

- Apr 25, 2018 3:56:43 PM

- Posted by Maria Alejandra Calcetero

- Topics: Education, NAO, Curriculum, Interaction

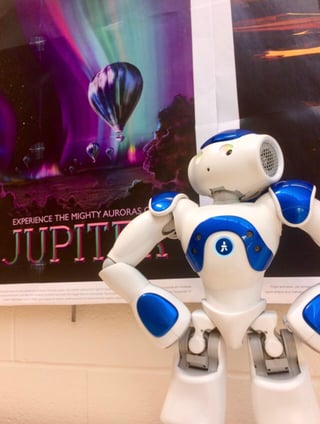

Feature a Teacher: NAO as a tool for fun and engaging project based-learning activities.

Tobe Roberts is an Educational Technologist at Bergen County Technical Schools, he has been using the NAO Robot to introduce a lesson, deliver exit ticket questions, create simulations with role play for the students utilizing the robot. Mr. Roberts created Pony Express simulation, Star Trek StarFleet Academy simulation for the topic of forms of Energy and NASA Space Flight simulation.

- 0 Comments

- Apr 25, 2018 3:54:42 PM

- Posted by Maria Alejandra Calcetero

- Topics: Education, NAO, Curriculum

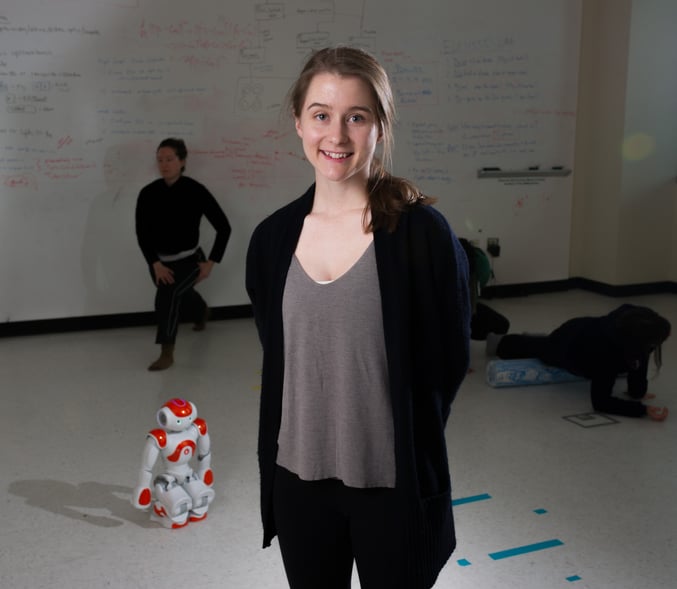

Feature a Teacher: NAO as a dancing tool to understand human-robot interaction.

Amy LaViers is an Assistant Professor at the University of Illinois at Urbana Champaign, and director of the RAD Lab a website of Robotics Automation and Dance (RAD). During her PhD Thesis she realized that Nao robot is the tool for her engaging for the public and researches alike.

- 0 Comments

- Apr 25, 2018 3:53:19 PM

- Posted by Maria Alejandra Calcetero

- Topics: Robotics, NAO, Robots,, programming, Learning, Interaction

Feature a Teacher: NAO as a Programming Tool for Robotics Course

Nicholas Kosloski is a Technology Innovation Design and Engineering Teacher at Somers High School in Connecticut. He has been using the Nao robot as a tool throughout the Programming Unit of a Robotics course. There are many other tools he uses including VEX robotics. This serves as the Humanoid section of the unit.

- 0 Comments

- Apr 25, 2018 3:52:15 PM

- Posted by Maria Alejandra Calcetero

- Topics:

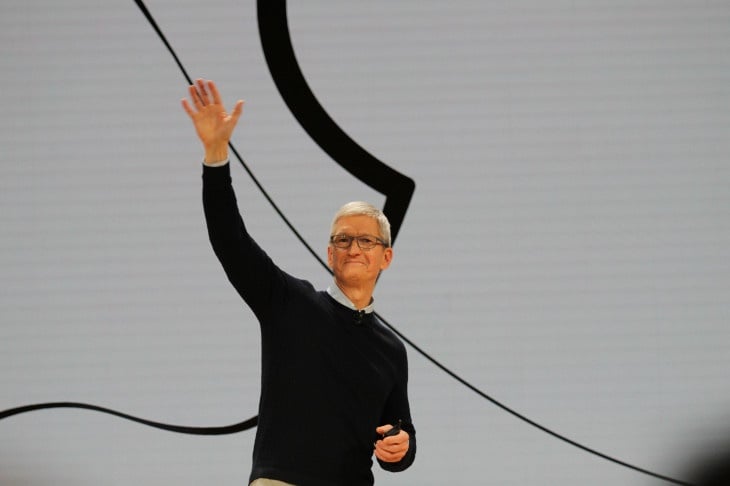

Big announcements for the Educational Market during Apple's event in Chicago

March 27, 2018- Chicago, USA

During Apple's Educational event, Apple CEO Tim Cook introduced different technologies for the educational market highlighting and reaffirming their constantly work on this field.

- 0 Comments

- Mar 28, 2018 3:21:36 PM

- Posted by Maria Alejandra Calcetero

- Topics: Education, Curriculum, Technology, Innovation

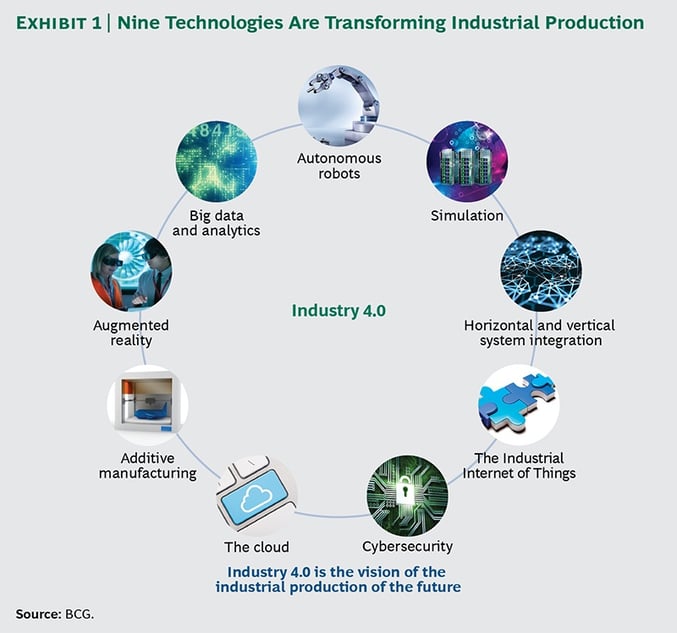

The Nine Technologies of Industry 4.0

Industry 4.0 is the beginning of a new digital industrial technology era that is transforming systems, sensors, machines, workpieces and IT. Industry 4.0 is making it possible to gather and analyze data across machines - creating a more efficient process with these nine technologies:

- 0 Comments

- Mar 28, 2018 1:30:00 PM

- Posted by Maria Alejandra Calcetero

- Topics:

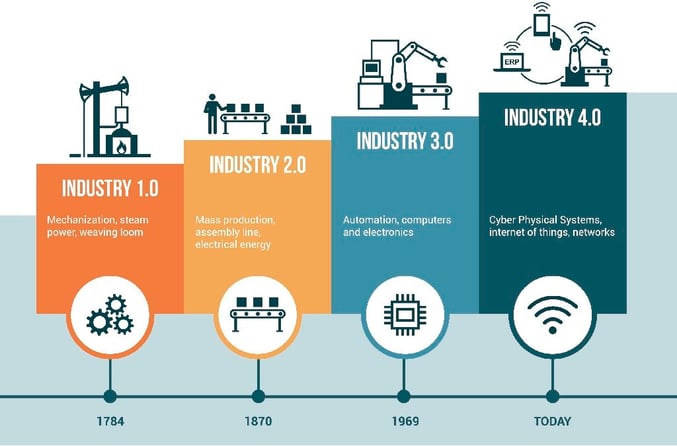

What are the effects of the Industry 4.0?

There are a few key differences between a traditional factory and an Industry 4.0 factory. In the current industry environment, providing a high-end quality service or product with the least cost is the key to success. Industrial factories want to achieve as much performance as possible to increase their profit as well as their reputation.

- 0 Comments

- Mar 14, 2018 10:00:00 AM

- Posted by Maria Alejandra Calcetero

- Topics:

Design Principles of the Industry 4.0

Industry 4.0 involves the heavy use of automation and data exchange in manufacturing environments, including areas such as cyber-physical systems, the Internet of Things (IoT) and cloud computing. With Industry 4.0, manufacturers will be able to operate "smarter" factories in which they can more easily tailor products to specific customers.

There are four design principles in Industry 4.0. These principles support companies in identifying and implementing Industry 4.0 scenarios. They include:

1. Interoperability: The ability of machines, devices, sensors, and people to connect and communicate with each other via the Internet of Things (IoT) or the Internet of People (IoP). Adding IoT will further automate the process to a significant extent

- 0 Comments

- Mar 7, 2018 5:40:00 PM

- Posted by Maria Alejandra Calcetero

- Topics:

Relevant Posts

Popular Posts

Subscribe to Email Updates

-

I Want To Learn MoreADDITIONAL INFORMATION